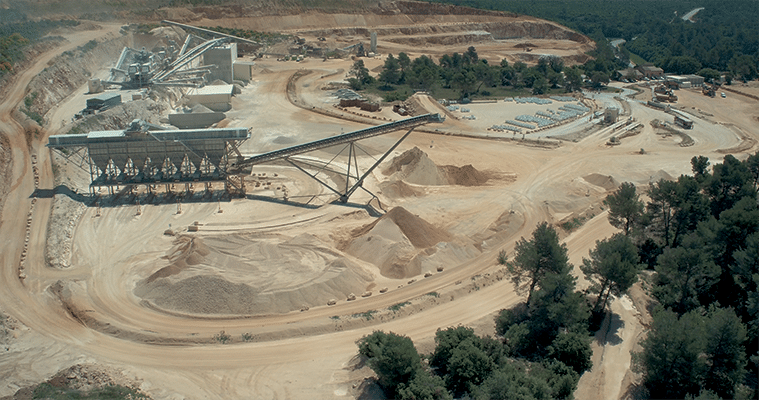

Most quarries use static or continuous weighing systems to control the quality of the mineral products they make and manage ingoing and outgoing flows of materials or finished products they deliver to their customers.

As a long-established Weighbridge manufacturer, Precia Molen harnesses its deep knowledge of the aggregates industry to constantly develop and widen its range of weighing products for the primary industry. It includes belt scales, on-board weighing systems, feed gates, weighing conveyors and management software.

Control your production remotely with our multi-site mobile application Weigh2Flow which displays the flow rates of your belt scales on your phone to let you monitor your production and organize any required action remotely, wherever you are.

Analyze, control and improve the performance of your production sites with our PERFORMANCE software.